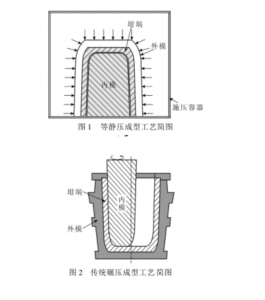

Graphite crucible ntau lawm tau hloov zuj zus mus nrog lub advent ntawm isostatic pressing technology, kos nws raws li cov txheej txheem tshaj plaws nyob rau hauv lub ntiaj teb no.Nyob rau hauv kev sib piv rau ib txwm ramming txoj kev, isostatic nias tau nyob rau hauv crucibles nrog ib tug zoo nkauj zoo nkauj, siab ceev, zog efficiency, thiab superior tiv thaiv oxidation.Daim ntawv thov kev kub siab thaum lub sij hawm molding ho txhim khu lub crucible qhov zoo nkauj, txo porosity thiab tom qab boosting thermal conductivity thiab corrosion kuj, raws li illustrated nyob rau hauv daim duab 1. Nyob rau hauv ib tug isostatic ib puag ncig, txhua feem ntawm lub crucible muaj ib yam molding siab, xyuas kom meej cov khoom sib xws.Txoj kev no, raws li tau piav qhia hauv daim duab 2, ua tau zoo tshaj cov txheej txheem ramming ib txwm, ua rau muaj kev txhim kho loj heev hauv kev ua haujlwm crucible.

1. Cov Lus Qhia Teeb Meem

Ib qho kev txhawj xeeb tshwm sim nyob rau hauv cov ntsiab lus ntawm aluminium alloy rwb thaiv tsev tiv thaiv hlau crucible rauv siv rammed graphite crucibles, nrog rau lifespan ntawm kwv yees li 45 hnub.Tom qab tsuas yog 20 hnub ntawm kev siv, pom pom kev poob qis hauv thermal conductivity, nrog rau micro-cracks ntawm lub crucible sab nrauv.Nyob rau theem tom ntej ntawm kev siv, kev poob qis hauv thermal conductivity yog tshwm sim, ua rau lub crucible yuav luag tsis yog-conductive.Tsis tas li ntawd, ntau cov kab nrib pleb tsim, thiab cov xim tsis zoo tshwm sim ntawm lub crucible sab saum toj vim oxidation.

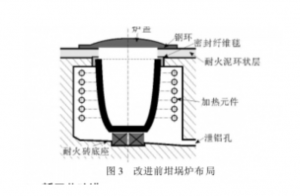

Thaum kuaj xyuas lub qhov cub hluav taws xob, raws li qhia hauv daim duab 3, lub hauv paus tsim los ntawm cov pob zeb refractory yog siv, nrog rau cov cua kub hauv qab ntawm cov hlau tsis kam nyob 100 hli saum lub hauv paus.Lub crucible sab saum toj yog kaw siv asbestos fiber pam, nyob ib ncig ntawm 50 mm los ntawm cov ntug sab nrauv, nthuav tawm qhov tseem ceeb puas ntawm sab hauv ntug ntawm lub crucible sab saum toj.

2. Kev txhim kho thev naus laus zis tshiab

Kev Txhim Kho 1: Kev siv Isostatic Pressed Clay Graphite Crucible (nrog rau qhov kub thiab txias Oxidation Resistant Glaze)

Kev siv cov crucible no tseem ceeb txhim kho nws daim ntawv thov nyob rau hauv aluminium alloy rwb thaiv tsev rauv, tshwj xeeb tshaj yog nyob rau hauv cov nqe lus ntawm oxidation kuj.Graphite crucibles feem ntau oxidize ntawm qhov kub siab tshaj 400 ℃, thaum lub rwb thaiv tsev kub ntawm aluminium alloy furnaces nyob nruab nrab ntawm 650 thiab 700 ℃.Crucibles uas tsis tshua muaj kub oxidation-resistant glaze tuaj yeem ua rau cov txheej txheem oxidation ntawm qhov kub siab tshaj 600 ℃, ua kom lub sijhawm ntev thermal conductivity.Tib lub sijhawm, nws tiv thaiv kev txo qis vim oxidation, ncua lub crucible lifespan.

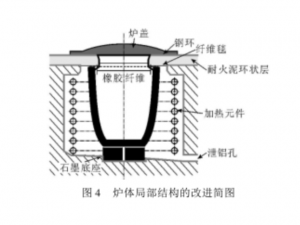

Kev txhim kho 2: Rauv Base Siv Graphite ntawm tib yam khoom raws li Crucible

Raws li tau piav qhia hauv daim duab 4, siv lub hauv paus graphite ntawm tib yam khoom raws li lub crucible kom tsis txhob muaj cua sov ntawm lub crucible hauv qab thaum lub sij hawm cua sov.Qhov no mitigates kub gradients tshwm sim los ntawm cov cua kub tsis sib xws thiab txo qhov nyiam ntawm cov kab nrib pleb uas tshwm sim los ntawm cov cua sov hauv qab tsis sib xws.Lub siab graphite puag kuj lav kev txhawb nqa ruaj khov rau lub crucible, ua raws nws hauv qab thiab txo qis kev ntxhov siab vim kev puas tsuaj.

Kev Txhim Kho 3: Kev Txhim Kho Hauv Ib Cheeb Tsam ntawm Lub Rauv (Daim duab 4)

- Txhim kho sab hauv ntawm lub qhov cub npog, tiv thaiv kev hnav ntawm lub crucible sab saum toj thiab ua kom lub cub tawg zoo dua.

- Xyuas kom cov hlau tsis kam yog qib nrog lub crucible hauv qab, lav kom txaus cua sov hauv qab.

- Txo qhov cuam tshuam ntawm sab saum toj fiber ntau daim pam ntsaws ruaj ruaj ntawm crucible cua sov, ua kom muaj cua sov txaus ntawm lub crucible sab saum toj thiab txo cov teebmeem ntawm qhov kub thiab txias oxidation.

Kev Txhim Kho 4: Refining Crucible Usage Processes

Ua ntej siv, preheat lub crucible nyob rau hauv lub cub tawg ntawm kub hauv qab no 200 ℃ rau 1-2 teev kom tshem tawm noo noo.Tom qab preheating, sai nce qhov kub thiab txias mus rau 850-900 ℃, txo lub sij hawm nyob ntawm 300-600 ℃ kom txo oxidation nyob rau hauv qhov kub thiab txias.Tom qab ntawd, txo qhov kub thiab txias rau qhov ua haujlwm kub thiab qhia cov khoom siv ua kua txhuas rau kev ua haujlwm ib txwm muaj.

Vim muaj kev cuam tshuam corrosive ntawm refining tus neeg sawv cev ntawm crucibles, ua raws li kev cai siv kom raug.Kev tshem tawm slag tsis tu ncua yog qhov tseem ceeb thiab yuav tsum tau ua thaum lub crucible kub, vim kev ntxuav slag yuav nyuaj rau lwm yam.Kev soj ntsuam ceev ceev ntawm lub crucible thermal conductivity thiab muaj kev laus ntawm cov phab ntsa crucible yog qhov tseem ceeb nyob rau theem tom ntej ntawm kev siv.Kev hloov pauv raws sij hawm yuav tsum tau ua kom tsis txhob muaj lub zog tsis tsim nyog thiab cov kua txhuas tawm.

3. Cov txiaj ntsig kev txhim kho

Lub neej ntev ntawm kev txhim kho crucible yog qhov tsim nyog, tswj xyuas thermal conductivity rau lub sijhawm ntev, tsis muaj qhov tawg ntawm qhov chaw.Cov neeg siv tswv yim qhia txog kev txhim kho kev ua tau zoo, tsis tsuas yog txo cov nqi tsim khoom tab sis kuj tseem txhim kho kev tsim khoom.

4. Cov lus xaus

- Isostatic pressed av nplaum graphite crucibles outperform ib txwm crucibles nyob rau hauv cov nqe lus ntawm kev ua tau zoo.

- Cov qauv ntawm lub cub tawg yuav tsum phim qhov loj thiab cov qauv ntawm lub crucible rau kev ua haujlwm zoo.

- Kev siv crucible zoo txuas ntxiv nws txoj sia, tswj cov nqi tsim khoom zoo.

Los ntawm kev tshawb fawb zoo thiab kev ua kom zoo ntawm cov tshuab hluav taws xob hluav taws xob, kev txhim kho kev ua tau zoo thiab kev ua neej nyob ua rau muaj txiaj ntsig zoo rau kev ua haujlwm ntau lawm thiab txuag nqi.

Post lub sij hawm: Dec-24-2023