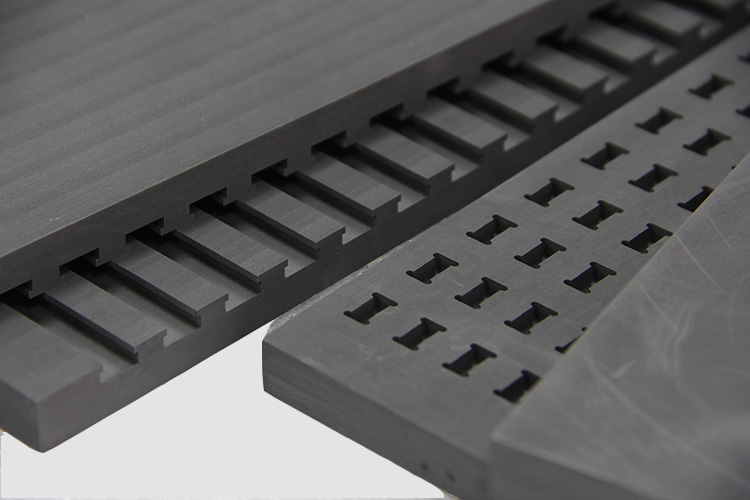

CNC customized graphite phaj

Nta

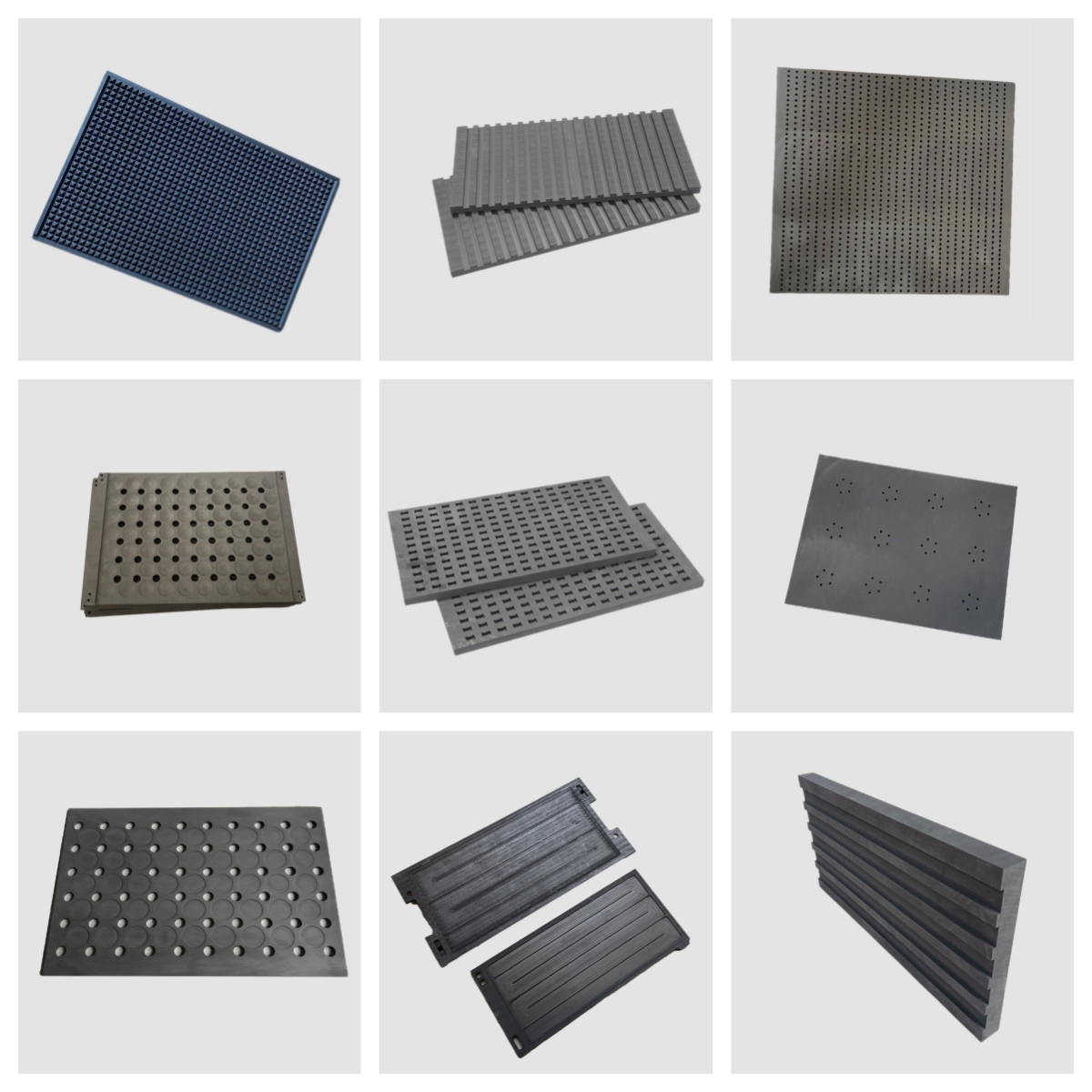

1) Cov ntaub ntawv refractory: Hauv kev lag luam smelting, graphite daim hlau yog siv los tsim cov graphite crucibles, ua cov tshuaj tiv thaiv rau steel ingots, thiab raws li magnesia carbon bricks rau hauv ob sab phlu ntawm smelting furnaces.

2) Cov khoom siv hluav taws xob: Hauv kev lag luam hluav taws xob, graphite yog dav siv los ua electrodes, txhuam, carbon tubes, thiab coatings rau TV raj.

3) Hnav cov ntaub ntawv resistant thiab lubricants: Nyob rau hauv ntau yam khoom siv, graphite daim hlau yog siv los hnav resistant thiab lubricating cov ntaub ntawv, uas muaj peev xwm swb ntawm ib tug ceev ntawm 100m / s nyob rau hauv qhov kub ntawm -200 mus rau 2000 ℃ tsis muaj los yog siv tsawg heev. lubricating roj.

4) Cov khoom siv sealing: Siv cov graphite hloov tau raws li cov piston nplhaib gaskets, sealing rings, thiab lwm yam rau cov twj centrifugal, dej turbines, chav turbines, thiab cov khoom thauj corrosive media.

5) Corrosion resistant khoom: Siv graphite daim hlau ua cov hlab ntsha, cov kav dej, thiab cov khoom siv, nws tuaj yeem tiv taus corrosion ntawm ntau yam corrosive gases thiab kua thiab yog dav siv nyob rau hauv departments xws li roj av, tshuaj, thiab hydrometallurgy.

6) thermal rwb thaiv tsev, kub-resistant, thiab hluav taws xob tiv thaiv cov ntaub ntawv: Graphite daim hlau yuav siv tau raws li neutron moderators nyob rau hauv nuclear reactors, raws li zoo raws li nozzles, qhov ntswg cones, aerospace khoom qhov chaw, thermal rwb thaiv tsev ntaub ntawv, hluav taws xob tiv thaiv cov ntaub ntawv, thiab lwm yam.

1. Zoo isotropy, yam ntxwv ywj siab ntawm qhov loj, zoo, thiab kev coj ua qauv;

2. Uniform qauv, ntom, thiab muaj zog antioxidant muaj peev xwm;

3. Zoo heev tus kheej lubrication;

4. Zoo tiv thaiv tshuaj corrosion;

5. High thermal conductivity thiab thermal stability kev ua tau zoo;

6. Txhim kho txhua yam muaj zog thiab cuam tshuam tsis kam;

7. Yooj yim rau tshuab thiab tuaj yeem ua tiav rau hauv ntau cov duab geometric raws li qhov yuav tsum tau ua.

Thaum siv lub twj tso kua mis tshiab, xyuam xim rau cov kev taw qhia ntawm lub cev muaj zog thiab tsis txhob txuas nws mus rau qhov rov qab iav.Ntev rov qab tig ntawm lub twj tso kua mis yuav ua rau cov hniav puas.

Cov plua plav ntau dhau hauv lub twj tso kua mis qhov chaw ua haujlwm thiab tsis pom huab cua tsis txaus tuaj yeem ua kom cov hniav hnav thiab txo cov hniav lifespan.

Qhov chaw ntub dej tuaj yeem ua rau xeb ntawm cov hniav thiab cov phab ntsa rotor.Thaum pib lub twj tso kua mis, cov khoom siv ntawm cov hniav yuav tsum tsis txhob muab pov tseg, vim tias kev ntxhov siab tsis sib xws tuaj yeem ua rau cov hniav puas.Hauv qhov no, cov hniav yuav tsum tau kuaj xyuas thiab ntxuav ua ntej.

Kev hloov pauv ntau zaus thaum siv lub twj tso kua mis ua rau muaj kev cuam tshuam ntau ntxiv thaum lub sij hawm cov hniav ejection, txo lub neej ntawm cov hniav.

Cov hniav tsis zoo tuaj yeem ua rau txo qis kev ua haujlwm ntawm lub twj tso kua mis lossis kev puas tsuaj rau lub tog raj kheej phab ntsa, yog li nws yuav tsum tau zam.

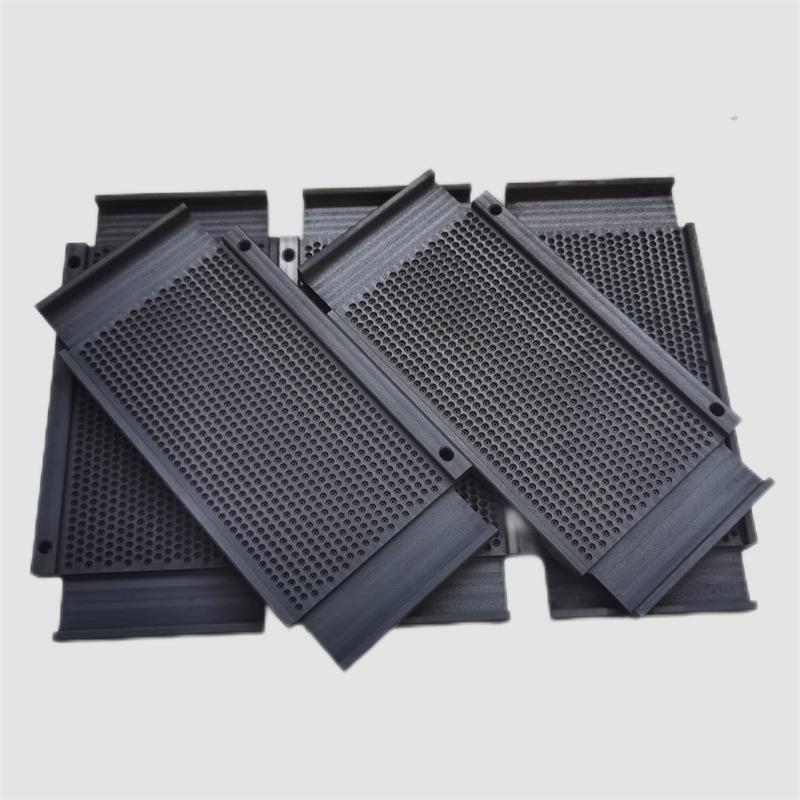

1. Muaj peev xwm ua tau zoo, muaj peev xwm muab cov kev qhia tshwj xeeb thiab spliced graphite daim hlau.

2. Peb tuaj yeem muab cov khoom graphite rau extrusion molding, vibration molding, molding, thiab isostatic pressing molding raws li xav tau.

3. Raws li cov kev xav tau sib txawv, cov khoom siv graphite xws li graphite daim hlau tuaj yeem raug oxidation tsis kam kho, kev kho impermeability, thiab kev kho kom muaj zog los txhim kho lawv cov kev ua tau zoo thiab kev pabcuam lub neej.