Carbon Bonded Silicon Carbide Crucibles

Nta

Melting hlau thiab alloys: Graphite SiC Crucibles yog siv nyob rau hauv melting hlau thiab alloys, xws li tooj liab, txhuas, zinc, kub, thiab nyiaj.Lub siab thermal conductivity ntawm graphite SiC crucibles ua kom ceev ceev thiab sib xws thaum tshav kub kub hloov mus, thaum lub siab melting point ntawm SiC muab zoo thermal stability thiab tsis kam rau thermal shock.

Kev tsim khoom semiconductor: Graphite SiC crucibles tuaj yeem siv rau kev tsim khoom semiconductor wafers thiab lwm yam khoom siv hluav taws xob.Graphite SiC Crucibles 'siab thermal conductivity thiab stability ua rau lawv zoo tagnrho rau siv nyob rau hauv high-temperature txheej txheem xws li tshuaj vapor deposition thiab siv lead ua loj hlob.

Kev tshawb fawb thiab kev loj hlob: Graphite SiC crucibles yog siv rau hauv cov ntaub ntawv tshawb fawb thiab kev loj hlob, qhov purity thiab stability yog qhov tseem ceeb.Lawv yog siv nyob rau hauv synthesis ntawm advanced cov ntaub ntawv xws li ceramics, composites, thiab alloys.

1. Cov ntaub ntawv zoo: Peb cov SiC Crucibles yog tsim los ntawm cov khoom siv raw khoom zoo.

2.High mechanical zog: Peb cov crucibles muaj lub zog txhua yam ntawm qhov kub thiab txias, ua kom muaj zog thiab ua haujlwm ntev.

3.Excellent thermal kev ua tau zoo: Peb cov SiC crucibles muab kev ua haujlwm zoo thermal, ua kom koj cov ntaub ntawv yaj sai thiab ua tau zoo.

4.Anti-corrosion zog: Peb SiC Crucibles muaj cov khoom tiv thaiv corrosion, txawm tias kub kub.

5.Electrical rwb thaiv tsev tsis kam: Peb cov crucibles muaj cov hluav taws xob rwb thaiv tsev zoo heev, tiv thaiv kev puas tsuaj hluav taws xob.

6.Professional technology txhawb: Peb muab kev tshaj lij thev naus laus zis los txhawb peb cov neeg siv khoom txaus siab rau lawv cov kev yuav khoom.

7.Customization muaj: Peb muab customization xaiv rau peb cov neeg muas zaub.

Silicon carbide crucible, tseem hu ua carbon bonded silicon carbide crucible, yog ib qho tseem ceeb rau lub cub tawg ntim dav siv nyob rau hauv lub chaw soj nstuam thiab ntau yam kev lag luam txheej txheem.Cov crucibles no yog ua los ntawm cov khoom siv silicon carbide thiab muaj kev tiv thaiv zoo rau kub kub, oxidation thiab corrosion.Qhov no, nyob rau hauv lem, tso cai rau lub crucible tiv taus hnav thiab corrosion txawm nyob rau hauv huab cua kub tej yam kev mob.

Ib qho ntawm cov yam ntxwv ntawm silicon carbide crucibles yog lawv cov tshuaj inertness.Lawv kuj muaj cov hluav taws xob rwb thaiv tsev zoo heev thiab nthuav tawm cov thermal conductivity zoo.Cov crucibles no yog kub-resistant rau kub tshaj 2000 ° C, ua rau lawv zoo tagnrho rau melting point kev txiav txim thiab kev kho cua sov thwmsim nrog ultra-siab kub cov ntaub ntawv los yog tshuaj reagents.

Silicon carbide crucibles yog dav siv nyob rau hauv ntau yam teb.Hauv cov chaw soj ntsuam chemistry, lawv feem ntau siv rau kev kub ntxhov thiab kev sim.Qee qhov kev siv tshwj xeeb suav nrog kev npaj cov qauv molten, melting ntawm tshwj xeeb iav fibers, thiab kev ua cov fused silica.Lawv tuaj yeem pab txhawb cov txheej txheem xws li casting, sintering thiab kev kho cua sov.

Ntxiv nrog rau cov ntawv thov kev sim, silicon carbide crucibles kuj ua lub luag haujlwm tseem ceeb hauv kev tsim khoom lag luam.Hauv kev lag luam steel smelting, hlau tsim, semiconductor ua, polymer cov ntaub ntawv ua thiab lwm yam teb, lub crucible yog ib tug indispensable cuab tam.

Thaum siv silicon carbide crucibles, muaj qee qhov kev ceev faj uas yuav tsum tau coj los xyuas kom meej qhov ua tau zoo:

1. Ua ntej siv thawj zaug, lub crucible yuav tsum tau ntxuav kom huv si thiab preheated nyob rau hauv qhov kub ntawm 200 ℃ -300 ℃ rau 2-3 teev.Cov txheej txheem no tshem tawm cov impurities thiab noo noo, txo qhov kev pheej hmoo ntawm kev puas tsuaj los ntawm thermal expansion thiab contraction.

2. Thaum muab cov khoom nyob rau hauv lub crucible rau kev ua, tsis txhob tshaj lub peev xwm ntawm lub crucible.Qhov no ua kom muaj kev sib raug zoo ntawm huab cua nyob rau hauv lub cub tawg thiab ua kom muaj kev sib haum xeeb ntawm cov ntaub ntawv.

3. Yuav tsum tau saib xyuas thaum muab lub crucible rau hauv lub tshuab cua sov.Kev tswj cov cua kub ceev thiab qhov kub thiab txias yog qhov tseem ceeb los tiv thaiv qhov kub thiab txias hloov pauv uas tuaj yeem ua rau muaj kev puas tsuaj.

Hauv cov ntsiab lus, silicon carbide crucibles yog cov cuab yeej siv tau ntau yam thiab ruaj khov nrog cov ntawv thov tseem ceeb hauv ob chav kuaj thiab chaw tsim khoom.Cov crucibles no muaj cov thermal tsis kam thiab tshuaj lom neeg inertness, muab txoj hauv kev txhim khu kev qha thiab ua haujlwm tau zoo los ua cov tshuaj tiv thaiv kub kub thiab kev sim.Kev siv kom raug thiab kev saib xyuas kom zoo ua haujlwm tau zoo thiab txuas ntxiv lub neej kev pab cuam ntawm cov crucibles tseem ceeb no.

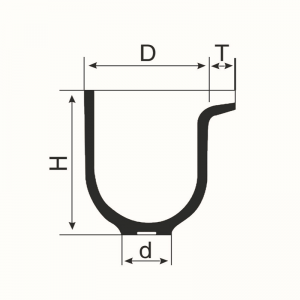

| Yam khoom | Sab nraud | Qhov siab | Sab hauv Dia | Hauv qab Dia |

| z803 ua | 620 | 800 | 536 ib | 355 |

| Z1800 | 780 ua | 900 | 680 | 440 |

| Z2300 | 880 ua | 1000 | 780 ua | 330 |

| z2700 ua | 880 ua | 1175 ib | 780 ua | 360 |