Silicon Carbide Thermocouple Protection Tube

Lub thermocouple tiv thaiv raj yog tsuas yog siv rau kev ntsuas kub ceev thiab raug thiab saib xyuas lub sijhawm ntawm cov hlau yaj kub hauv cov hlau tsis muaj hlau. Nws xyuas kom meej tias cov hlau yaj tseem nyob ruaj khov nyob rau hauv qhov zoo tshaj plaws casting kub ntau yam los ntawm koj, yog li xyuas kom zoo castings.

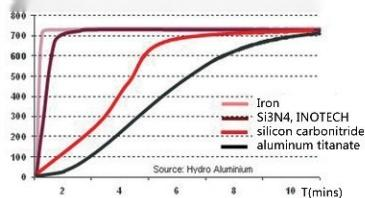

Cov thermal conductivity zoo heev, muab cov lus teb ceev ceev thiab ntsuas qhov tseeb ntawm cov hlau ua kua kub thaum hloov pauv kub.

Zoo oxidation tsis kam, corrosion kuj, thiab thermal shock kuj.

Zoo heev tsis kam rau mechanical cuam tshuam.

Tsis muaj kab mob rau cov kua hlau.

Lub neej ntev kev pab cuam, yooj yim installation, thiab hloov

Melting Rauv: 4-6 lub hlis

Rwb thaiv tsev rauv: 10-12 lub hlis

Cov qauv khoom

| Xov | L (mm) | OD (mm) | D (mm) |

| 1/2 " | 400 | 50 | 15 |

| 1/2 " | 500 | 50 | 15 |

| 1/2 " | 600 | 50 | 15 |

| 1/2 " | 650 | 50 | 15 |

| 1/2 " | 800 | 50 | 15 |

| 1/2 " | 1100 | 50 | 15 |