Silica Carbide Crucible rau Melting Aluminium rau Casting

Qhov kawg Crucible rau High-Performance Hlau Melting

Puas yog koj tab tom nrhiav rau lub crucible uas tuaj yeem tiv taus qhov kub thiab txias, muab thermal conductivity zoo, thiab muaj kev tiv thaiv corrosion zoo dua? Saib tsis ntxiv - pebSilicon Carbide Cruciblesyog engineered kom xa exceptional kev ua tau zoo nyob rau hauv lub hardest melting ib puag ncig. Txawm hais tias koj tab tom ua haujlwm nrog cov hluav taws xob lossis cov hluav taws xob hluav taws xob, cov crucibles no yog qhov hloov pauv kev ua si, txhim kho koj txoj haujlwm ua haujlwm tau zoo thaum txuas lub neej kev pabcuam ntawm koj cov khoom siv.

Ntsiab nta

- Kub-kub Resistance

Silicon carbide crucibles tau yooj yim tswj qhov kub siab tshaj 1600 ° C, ua rau lawv zoo tagnrho rau melting ntau yam hlau, suav nrog txhuas, tooj liab, thiab cov hlau muaj txiaj ntsig. - Zoo heev thermal conductivity

Nrog superior thermal conductivity, cov crucibles tso cai rau sai thiab ntau npaum li cas melting cycles. Qhov no txhais tau hais tias tsawg zog siv thiab luv luv lub sij hawm ntau lawm. - Zoo tshaj Corrosion Resistance

Lub hauv paus corrosion kuj ntawm silicon carbide ua kom lub neej ntev, txawm tias thaum melting reactive hlau. Cov yeeb yam no ua rau txo qis qhov xav tau kev hloov pauv ntau zaus, txuag koj cov nyiaj thiab sijhawm poob. - Tsawg Thermal Expansion

Silicon carbide crucibles muaj cov coefficient tsawg ntawm thermal expansion, txhais tau tias lawv tswj cov qauv kev ncaj ncees txawm tias thaum hloov kub ceev, txo qhov kev pheej hmoo ntawm kev tawg lossis tsis ua haujlwm. - Cov khoom siv tshuaj ruaj khov

Cov crucibles no muaj qhov cuam tshuam tsawg kawg nkaus nrog cov hlau molten, kom ntseeg tau tias qhov purity ntawm koj cov melts, tshwj xeeb tshaj yog rau cov ntaub ntawv rhiab heev xws li high-purity aluminium casting.

Khoom Specifications

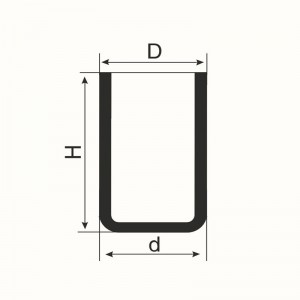

| Qauv | Qhov siab (mm) | Sab nraud Dia (mm) | Hauv qab Dia (mm) |

|---|---|---|---|

| CC1300X935 | 1300 | 650 | 620 |

| CC1200X650 | 1200 | 650 | 620 |

| CC650X640 | 650 | 640 | 620 |

| CC800X530 | 800 | 530 | 530 |

| CC510X530 | 510 | 530 | 320 |

Cov lus qhia txog kev tu thiab siv

- Preheat Maj mam: Ib txwm preheat koj crucible maj mam kom tsis txhob thermal shock.

- Ntxuav: Ua kom lub puab nto du thiab huv si kom tsis txhob muaj hlau adhesion.

- Cia: Khaws rau hauv qhov chaw qhuav, qhov cua kom tiv thaiv kom tsis txhob ya raws.

- Hloov lub voj voog: Tshawb xyuas tsis tu ncua rau cov cim ntawm hnav thiab tsim kua muag; hloov raws sij hawm kom ntseeg tau tias qhov ua tau zoo tshaj plaws.

Vim li cas thiaj xaiv peb?

Peb leverage peb xyoo ntawm kev paub nyob rau hauv hlau casting coj koj silicon carbide crucibles uas ua tau zoo tshaj qhov kev sib tw. Peb cov kev txawj ntse nyob rau hauv optimizing tus tsim thiab cov khoom muaj pes tsawg leeg kom tau raws li qhov xav tau tshaj plaws kev lag luam daim ntaub ntawv. Nrog peb, koj tsis yog yuav khoom xwb-koj koom tes nrog pab pawg uas nkag siab txog koj cov kev cov nyom thiab muab cov kev daws teeb meem raws li koj xav tau.

Qhov Zoo Tshaj Plaws:

- 20% kev pab cuam lub neej ntev dua piv rau kev lag luam-tus qauv crucibles.

- Tshwj xeeb hauv qhov chaw qis-oxidation thiab siab thermal efficiency, tshwj xeeb tshaj yog rau txhuas thiab tooj liab casting industries.

- Thoob ntiaj teb ncav cuag nrog cov neeg koom tes ntseeg siab hauv Tebchaws Europe thiab North America.

FAQs

Q1: Cov nqe lus them nqi dab tsi koj muab?

Peb xav tau 40% tso nyiaj, nrog qhov nyiaj tshuav them ua ntej xa khoom. Peb muab cov duab ntxaws ntxaws ntawm koj qhov kev txiav txim ua ntej ua zaub mov xa tuaj.

Q2: Kuv yuav ua li cas thiaj li tuav cov crucibles thaum siv?

Txhawm rau kom tau txais txiaj ntsig zoo tshaj plaws, maj mam preheat thiab ntxuav tom qab txhua qhov siv los txuas lawv lub neej.

Q3: Nws yuav siv sij hawm ntev npaum li cas los xa khoom?

Lub sij hawm xa tuaj ntau li ntawm 7-10 hnub nyob ntawm qhov kev txiav txim loj thiab qhov chaw.

Tau kov!

Xav kawm ntxiv los yog thov ib daim ntawv tsocai? Tiv tauj peb hnub no kom pom tias peb li casSilicon Carbide Cruciblestuaj yeem hloov kho koj cov haujlwm hlau casting.