Graphiteyog ib qho allotrope ntawm carbon, uas yog grey dub, opaque khoom nrog ruaj khov khoom thiab corrosion kuj. Nws tsis yooj yim reactive nrog acids, alkalis, thiab lwm yam tshuaj, thiab muaj qhov zoo xws li kub tsis kam, conductivity, lubrication, plasticity, thiab thermal shock resistance.

Yog li ntawd, nws yog feem ntau siv rau:

1.Refractory cov ntaub ntawv: Graphite thiab nws cov khoom muaj cov khoom ntawm qhov kub thiab txias tsis kam thiab lub zog, thiab feem ntau yog siv nyob rau hauv metallurgical kev lag luam los tsim graphite crucibles. Hauv steelmaking, graphite feem ntau yog siv los ua tus neeg sawv cev tiv thaiv rau steel ingots thiab ua ib lub hauv ob sab phlu rau metallurgical furnaces.

2.Cov khoom siv hluav taws xob: siv hauv kev lag luam hluav taws xob los tsim cov khoom siv hluav taws xob, txhuam hniav, cov pa roj carbon monoxide, cov roj carbon raj, cov khoom siv hluav taws xob zoo rau mercury zoo tam sim no transformers, graphite gaskets, xov tooj qhov chaw, coatings rau TV raj, thiab lwm yam.

3.Graphite muaj cov tshuaj ruaj khov zoo, thiab tom qab kev ua haujlwm tshwj xeeb, nws muaj cov yam ntxwv ntawm kev tiv thaiv corrosion, zoo thermal conductivity, thiab tsis tshua muaj permeability. Nws yog dav siv nyob rau hauv zus tau tej cov tshav kub exchangers, tshuaj tiv thaiv tank, condensers, combustion towers, nqus yees, coolers, heaters, lim, thiab twj tso kua mis khoom. Dav siv nyob rau hauv industrial sectors xws li petrochemical, hydrometallurgy, acid-base ntau lawm, hluavtaws fibers, thiab papermaking.

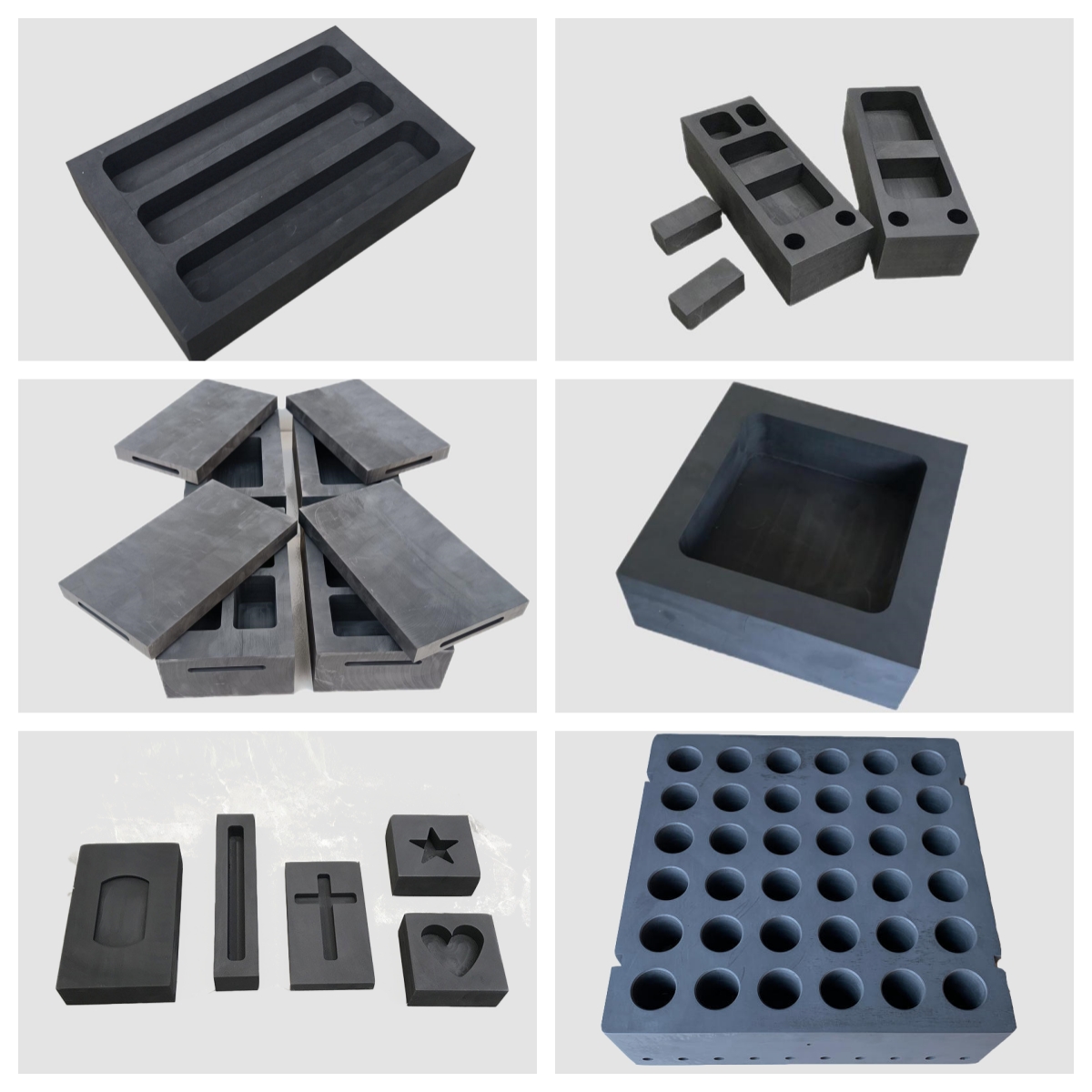

4.Ua casting, xuab zeb tig, molding, thiab high-temperature metallurgical cov ntaub ntawv: Vim lub thermal expansion coefficient me me ntawm graphite thiab nws muaj peev xwm tiv taus cov kev hloov ceev ceev txias thiab cua sov, nws yuav siv tau los ua pwm rau iav. Tom qab siv graphite, cov hlau dub tuaj yeem tau txais qhov tseeb casting qhov ntev, siab du du, thiab siab tawm los. Nws tuaj yeem siv yam tsis muaj kev ua haujlwm lossis kev ua haujlwm me ntsis, yog li txuag nyiaj ntau ntawm cov hlau.

5.Qhov kev tsim cov khoom siv tawv tawv thiab lwm cov txheej txheem hlau metallurgy feem ntau yog siv cov khoom siv graphite los ua cov nkoj ceramic rau nias thiab sintering. Kev ua cov khoom siv lead ua kev loj hlob crucibles, lub regional refining ntim, kev txhawb nqa fixtures, induction heaters, thiab lwm yam rau monocrystalline silicon tsis tuaj yeem sib cais los ntawm high-purity graphite. Tsis tas li ntawd, graphite kuj tseem siv tau los ua cov graphite cais thiab lub hauv paus rau lub tshuab nqus tsev smelting, nrog rau cov khoom xws li cov kav dej kub kub, cov pas nrig, daim hlau, thiab kab sib chaws.

Post lub sij hawm: Sep-21-2023