Muaj Crucible Rau Copper Scrap Melting Rauv

Khoom Taw Qhia: Crucible hauv Foundry

Hauv kev lag luam foundry, kev xaiv ntawm crucible tuaj yeem cuam tshuam qhov ua tau zoo thiab zoo ntawm cov txheej txheem hlau casting. PebMuaj Cruciblesyog tsim los nrog cov yam ntxwv siab heev uas ua tau raws li qhov xav tau ntawm aluminium melting thiab casting, ua rau lawv yog cov cuab yeej tseem ceeb rau cov kws tshaj lij.

Ntsiab nta

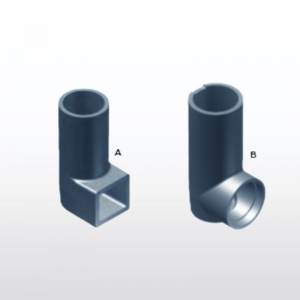

- Tsim tshiab: PebMuaj Cruciblesyog tsim los nrog lub hauv qab-ntws feature uas tso cai rau meej thiab tswj kev nchuav ntawm molten aluminium. Qhov kev tsim no minimizes spillage thiab ua kom muaj kev ua haujlwm du, txhim kho cov khoom lag luam hauv qhov chaw tsim khoom.

- Cov ntaub ntawv zoo tshaj: Crafted los ntawm upgraded formulations ntawm silicon carbide thiab av nplaum graphite, peb crucibles boasts tshwj xeeb oxidation kuj, corrosion kuj, thiab ceev thermal conductivity. Cov kev txhim kho no ua kom lub neej ntev thiab txhim khu kev qha hauv qhov chaw kub kub

- Ceev thiab ua tau zoo Melting: Lub siab thermal conductivity ntawm peb cov crucibles txhais tau hais tias lawv yaj aluminium sai thiab zoo, txuag lub sij hawm thiab txo nqi zog. Peb cov khoom raug tsim los ua kom zoo dua cov txheej txheem melting, uas yog ib qho tseem ceeb hauv kev teeb tsa ceev ceev (

- Kev ua haujlwm tsis muaj roj: Ib qho tshwj xeeb ntawm peb cov crucibles yog lawv lub peev xwm los tiv thaiv cov pa roj carbon monoxide thaum lub sij hawm melting. Qhov no ua kom lub purity ntawm txhuas, tiv thaiv qhov zoo ntawm cov khoom kawg

Vim Li Cas Xaiv Peb Cov Crucibles?

Hauv kev lag luam uas qhov zoo thiab kev ua tau zoo yog qhov tseem ceeb, pebMuaj Cruciblesmuab ntau yam zoo:

- Txhim khu Durability: Peb cov crucibles tau kho dua tshiab los tiv thaiv oxidation zoo dua li cov khoom qub. Qhov no tsis tsuas yog ncua lawv lub neej tab sis kuj ua kom muaj kev ua tau zoo ib yam dhau sijhawm

- Kev daws teeb meem: Peb nkag siab tias txhua qhov chaw tsim khoom muaj cov kev cai tshwj xeeb. Yog li ntawd, peb muab cov crucibles customized raws li cov kev xav tau tshwj xeeb, kom ntseeg tau tias koj muaj cov cuab yeej zoo tshaj plaws rau koj txoj haujlwm.

- Kev txawj ntse thiab kev txhawb nqa: Backed los ntawm ntau xyoo ntawm kev paub nyob rau hauv lub foundry sector, peb muab kev txawj ntse thiab kev pab txhawb nqa los pab koj maximize lub efficiency ntawm koj cov hauj lwm. Peb txoj kev paub txuas ntxiv dhau ntawm cov khoom siv xwb; peb pab txhim kho cov txheej txheem melting thiab kev siv lub zog, pab koj ua tiav cov txiaj ntsig zoo dua

Lub Hom Phiaj

Cov khoom no yog qhov zoo tagnrho rau cov tswv lag luam, cov kws tshaj lij hlau, thiab cov lag luam koom nrog hauv kev lag luam aluminium casting. Yog tias koj tab tom nrhiav kev txhim khu kev qha, kev ua haujlwm siab crucibles uas ua kom zoo thiab ua haujlwm zoo, peb cov crucibles hauv qab yog cov tshuaj zoo meej.

Xaus

Hauv cov ntsiab lus, peb cov hauv qab-pob crucibles sawv tawm hauv kev lag luam foundry vim lawv cov qauv tsim tshiab, cov ntaub ntawv zoo dua, thiab tsom mus rau kev ua haujlwm zoo. Los ntawm kev xaiv peb cov crucibles, koj xyuas kom meej tsis yog tsuas yog lub purity ntawm koj txhuas, tab sis kuj lub neej ntev thiab kev cia siab ntawm koj cov hauj lwm casting.

Lub tuam txhab zoo

Peb txaus siab rau peb tus kheej ntawm peb txoj kev mob siab rau kev ua tau zoo thiab kev tsim kho tshiab. Peb cov txheej txheem ntau lawm, ua ke nrog peb cov kev paub txog kev lag luam dav dav, pab kom peb muab cov kev daws teeb meem zoo tshaj plaws rau koj cov kev xav tau ntawm cov foundry. Koom tes nrog peb rau qhov tsis sib xws thiab kev pabcuam hauv kev lag luam aluminium casting.