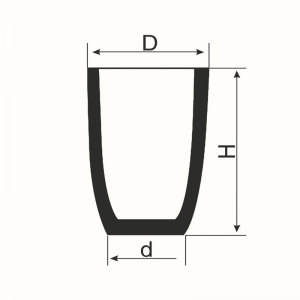

Khoom siv:

PebCylindrical Crucibleyog crafted los ntawm isostatically nias silicon carbide graphite, ib yam khoom uas muaj tshwj xeeb kub-kub kuj thiab zoo heev thermal conductivity, ua rau nws yog ib qho tseem ceeb cov cuab yeej rau industrial smelting daim ntaub ntawv.

- Silicon Carbide (SiC): Silicon carbide paub txog nws qhov hnyav hnyav thiab zoo heev rau hnav thiab corrosion. Nws tuaj yeem tiv taus cov tshuaj tiv thaiv kub kub, muab kev ruaj ntseg zoo dua txawm tias nyob rau hauv kev ntxhov siab thermal, uas txo qhov kev pheej hmoo ntawm kev tawg thaum lub sijhawm hloov pauv kub.

- Natural Graphite: Ntuj graphite xa cov thermal conductivity tshwj xeeb, kom ntseeg tau sai thiab sib xws thaum tshav kub kub faib thoob plaws hauv lub crucible. Tsis zoo li cov av nplaum-raws li graphite crucibles, peb cov cylindrical crucible siv high-purity ntuj graphite, uas txhim kho cov cua sov hloov efficiency thiab txo lub zog noj.

- ISostatic nias thev naus laus zis: tus crucible yog tsim siv siab iTostatic nias, kom muaj kev sib txawv nrog tsis muaj qhov tsis xws sab hauv lossis sab nraud. Cov cuab yeej no txhim kho lub zog thiab tawg tsis kam ntawm crucible, txuas ntxiv nws cov kav ntev hauv qhov chaw kub kub.

Kev ua tau zoo:

- Superior Thermal Conductivity: Lub Cylindrical Crucible yog tsim los ntawm cov khoom siv thermal conductivity uas tso cai rau kev xa tawm sai thiab txawm tias cua sov. Qhov no txhim khu kev ua tau zoo ntawm cov txheej txheem smelting thaum txo kev siv hluav taws xob. Piv nrog rau cov pa crucibles, thermal conductivity yog txhim kho los ntawm 15% -20%, ua rau cov roj tseem ceeb txuag thiab ntau lawm voj voog.

- Zoo corrosion kuj: Peb silicon carbide graphite crucibles yog heev resistant rau corrosive los ntawm molten hlau thiab tshuaj, ua kom lub stability thiab lub neej ntev ntawm lub crucible thaum lub sij hawm ntev siv. Qhov no ua rau lawv zoo tagnrho rau smelting aluminium, tooj liab, thiab ntau yam hlau alloys, txo cov txij nkawm thiab hloov zaus.

- Extended Service Life: Nrog nws cov high-density thiab high-strength qauv, lub lifespan ntawm peb cylindrical crucible yog 2 mus rau 5 zaug ntev dua li niaj hnub av nplaum graphite crucibles. Qhov kev tiv thaiv zoo tshaj rau kev tawg thiab hnav txuas ntxiv lub neej ua haujlwm, txo qis sijhawm thiab hloov cov nqi.

- High Oxidation Resistance: Ib qho tshwj xeeb tsim cov ntaub ntawv muaj pes tsawg leeg zoo tiv thaiv oxidation ntawm graphite, txo qis degradation ntawm qhov kub thiab txias ntxiv thiab txuas ntxiv lub neej ntawm crucible.

- Superior Mechanical Strength: Ua tsaug rau cov txheej txheem isostatic nias, lub crucible boasts exceptional mechanical zog, tuav nws cov duab thiab durability nyob rau hauv high-temperature ib puag ncig. Qhov no ua rau nws zoo tagnrho rau cov txheej txheem smelting uas xav tau kev kub siab thiab kev ruaj ntseg txhua yam.

Product Advantages:

- Cov txiaj ntsig ntawm cov khoom siv: Kev siv cov graphite thiab silicon carbide ua kom cov thermal conductivity thiab corrosion kuj, muab kev ua tau zoo nyob rau hauv qhov hnyav, qhov kub thiab txias.

- High-Density Structure: Isostatic pressing thev naus laus zis tshem tawm cov voids thiab cov kab nrib pleb, txhim kho lub crucible lub zog thiab lub zog thaum siv txuas ntxiv.

- High-Temperature Stability: Muaj peev xwm tiv taus qhov kub txog li 1700 ° C, qhov crucible no zoo tagnrho rau ntau yam smelting thiab casting txheej txheem uas muaj hlau thiab alloys.

- Energy Efficiency: Nws cov khoom siv hluav taws xob zoo tshaj plaws txo cov roj noj, thaum cov khoom siv ib puag ncig txo cov pa phem thiab pov tseg.

Xaiv peb cov Cylindrical Crucible uas ua tau zoo yuav tsis tsuas yog txhim kho koj cov khoom siv smelting, tab sis kuj txo qis kev siv hluav taws xob, txuas cov cuab yeej siv lub neej, thiab txo tus nqi tu, thaum kawg txhim kho kev tsim khoom.

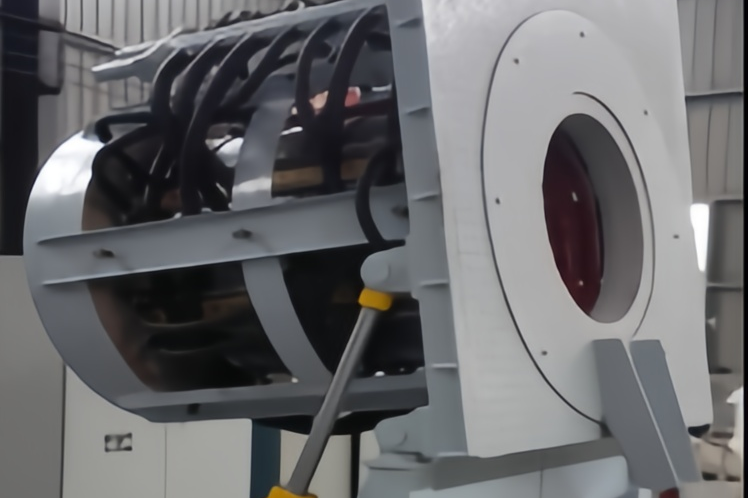

Nyob rau hauv niaj hnub metalworking thiab recycling industries, induction cua sov tau dhau los ua txoj kev nyiam rau cov txheej txheem melting npaum thiab meej. Kev xaiv ntawm crucible plays lub luag haujlwm tseem ceeb hauv kev ua kom cov txheej txheem no ua haujlwm zoo, tshwj xeeb tshaj yog nyob rau hauv induction furnaces. Peb tau tsimInduction Cua sov Cruciblessiv isostatic nias tshuab los muab kev ua haujlwm tsis sib xws hauv cov ntawv thov no.

Tsis zoo li tus qauv crucibles, uas tej zaum yuav tawm tsam nrog magnetic teb nyob rau hauv induction furnaces, peb crucibles yog tsim los ua kom sov los ntawm magnetic induction. Qhov kev tsim kho tshiab no tsis yog tsuas yog txhim kho lub zog ua haujlwm xwb tab sis kuj tseem txuas ntxiv lub neej ntawm crucible, ua rau nws yog qhov kev xaiv zoo tshaj plaws rau kev lag luam xws li txhuas rov ua dua tshiab thiab hlau casting.

Cov khoom sib nqus ntawm cov crucibles no yog qhov tseem ceeb tshwj xeeb rau cov neeg siv ntawm induction furnaces, qhov twg muaj peev xwm ua kom sov los ntawm induction tuaj yeem ua rau kom muaj txiaj ntsig tag nrho ntawm cov txheej txheem. Qhov no tsis tsuas yog txuag lub sijhawm tab sis kuj txo cov nqi hluav taws xob, ua rau nws muaj txiaj ntsig zoo rau kev lag luam.

Kev siv ntawm induction cua sov Crucibles

- Aluminium Recycling Industry:

- Nyob rau hauv kev lag luam aluminium recycled, corrosion kuj tseem ceeb heev vim muaj kev mob hnyav cuam tshuam rau hauv cov txheej txheem. Peb cov crucibles tau tsim tshwj xeeb los tswj cov cheeb tsam no, muab lub neej ntev tshaj li European crucibles ntau dua 20%.

- Lub siab thermal conductivity ua kom lub sij hawm melting sai, uas boosts productivity thiab txo lub zog noj.

- Induction rauv:

- Traditional crucibles feem ntau tsis muaj cov khoom sib nqus, uas tuaj yeem ua rau tsis muaj txiaj ntsig thaum siv rau hauv qhov cub induction. Peb induction cua sov crucibles yog engineered nrog sib nqus cua sov muaj peev xwm, txhais tau tias lub crucible nws tus kheej generates tshav kub, txhim kho tag nrho cov txheej txheem efficiency thiab ntxiv txo nqi zog.

- Nrog rau lub neej ntev tshaj li ib xyoos, cov crucibles no muaj txiaj ntsig zoo dua lawv cov neeg sib tw, txo qis sijhawm thiab hloov cov nqi.

- Lwm yam kev siv hlau Melting:

- Txawm hais tias rau tooj liab, zinc, lossis nyiaj melting txheej txheem, peb cov crucibles muab kev ua tau zoo, ua kom cov txiaj ntsig zoo ib yam thoob plaws ntau yam kev lag luam.

Kev tu thiab siv cov lus qhia rau induction cua sov Crucibles

Txhawm rau ua kom lub neej ntev thiab ua haujlwm tau zoo ntawm koj qhov Induction Cua sov Crucible, nws yog ib qho tseem ceeb uas yuav tsum ua raws li kev siv thiab kev saib xyuas kom zoo:

- Preheating: Maj mam ua kom sov lub crucible mus rau qhov xav tau kub kom tsis txhob thermal shock.

- Ntxuav: Ntxuav lub crucible tsis tu ncua kom tshem tawm cov khoom seem uas tuaj yeem cuam tshuam kev ua haujlwm thiab ua rau lub neej luv.

- Cia: Khaws cov crucibles nyob rau hauv ib qho chaw qhuav, txias kom tsis txhob raug ya raws los yog corrosive ntsiab uas yuav degrade cov khoom nyob rau lub sij hawm.

Cov kev coj ua no yuav pab xyuas kom meej tias koj lub crucible ua haujlwm ntawm qhov ua tau zoo tshaj plaws rau ntev, txo qhov zaus ntawm kev hloov pauv thiab kev saib xyuas.

Khoom Muag Khoom

Peb txaus siab los muab Induction Cua sov Crucibles tsim rau siab tshaj plaws durability thiab kev ua tau zoo. Peb cov crucibles feature isostatic pressing technology, uas ua kom zoo ib yam thiab lub zog, ua rau lawv tiv taus thermal shock thiab mechanical stress. Nrog lub peev xwm los tsim kom muaj cua sov los ntawm kev sib nqus induction, peb cov crucibles yog tsim tshwj xeeb rau induction rauv daim ntaub ntawv, qhov twg precision thiab lub zog efficiency yog qhov tseem ceeb.

Customization Options: Peb nkag siab tias txhua qhov kev lag luam muaj cov kev cai tshwj xeeb. Tias yog vim li cas peb muab tag nrho customizable crucibles, tailored kom tau raws li koj cov kev xav tau kev khiav hauj lwm. Txawm hais tias koj xav tau cov duab sib txawv, qhov loj me, lossis muaj pes tsawg leeg, peb pab pawg tau npaj ua haujlwm nrog koj los tsim cov kev daws teeb meem zoo tshaj plaws.

Kev them nyiaj yug Technical: Peb pab neeg mob siab rau muab kev txhawb nqa tag nrho los pab koj kom tau txais txiaj ntsig zoo tshaj plaws ntawm koj cov crucibles. Los ntawm kev teeb tsa thawj zaug mus rau cov lus qhia txog kev saib xyuas tsis tu ncua, peb nyob ntawm no los xyuas kom meej tias koj cov txheej txheem ua haujlwm tau zoo thiab ua tau zoo.

Hu rau Action

Yog tias koj tab tom nrhiav los txhim kho qhov ua tau zoo ntawm koj cov txheej txheem cua sov induction, peb Induction Cua sov Crucibles yog cov tshuaj zoo meej. Nrog isostatic nias thev naus laus zis, cov khoom siv hluav taws xob sib nqus zoo dua, thiab lub neej ntev ntev, cov crucibles no muab kev ntseeg siab thiab kev ua tau zoo uas koj lub lag luam xav tau kom nyob ua ntej hauv kev sib tw ua lag luam.

Tiv tauj peb hnub no kom paub ntau ntxiv txog peb cov kev daws teeb meem crucible thiab lawv tuaj yeem txhim kho koj cov txheej txheem ntau lawm.