Kub muag Hoobkas 50g Hluav Taws Kub Assay Smelting Kub Crucible

Nta

Tam sim no peb muaj cov neeg ua haujlwm tau zoo los daws cov lus nug los ntawm cov neeg siv khoom.Peb lub hom phiaj yog "100% cov neeg siv khoom txaus siab los ntawm peb cov khoom lag luam zoo, tus nqi nqe & peb cov neeg ua haujlwm pabcuam" thiab txaus siab rau qhov zoo heev ntawm cov neeg yuav khoom.Muaj ob peb lub Hoobkas, peb tuaj yeem muab ntau yam sib txawv ntawm Kub Muag Hoobkas 50g Hluav Taws Kub Ntsuas Smelting Kub Crucible, Peb tau saib xyuas ua ntej los teeb tsa lub koom haum ua lag luam me nrog koj mus ntev.Koj cov kev txheeb xyuas thiab cov lus qhia tau txais txiaj ntsig zoo heev.

Tam sim no peb muaj cov neeg ua haujlwm tau zoo los daws cov lus nug los ntawm cov neeg siv khoom.Peb lub hom phiaj yog "100% cov neeg siv khoom txaus siab los ntawm peb cov khoom lag luam zoo, tus nqi nqe & peb cov neeg ua haujlwm pabcuam" thiab txaus siab rau qhov zoo heev ntawm cov neeg yuav khoom.Nrog ob peb lub Hoobkas, peb tuaj yeem yooj yim muab ntau yam sib txawvTuam Tshoj Hluav Taws Kub Assay thiab Hluav Taws Xob Hluav Taws Xob, Peb cov khoom zoo yog ib qho ntawm cov kev txhawj xeeb loj thiab tau ua kom tau raws li tus neeg siv khoom tus qauv."Kev pabcuam cov neeg siv khoom thiab kev sib raug zoo" yog lwm qhov tseem ceeb uas peb nkag siab txog kev sib txuas lus zoo thiab kev sib raug zoo nrog peb cov neeg siv khoom yog lub zog tseem ceeb tshaj plaws los khiav nws ua lag luam mus ntev.

Melting hlau thiab alloys: Graphite SiC Crucibles yog siv nyob rau hauv melting hlau thiab alloys, xws li tooj liab, txhuas, zinc, kub, thiab nyiaj.Lub siab thermal conductivity ntawm graphite SiC crucibles ua kom ceev ceev thiab sib xws thaum tshav kub kub hloov mus, thaum lub siab melting point ntawm SiC muab zoo thermal stability thiab tsis kam rau thermal shock.

Kev tsim khoom semiconductor: Graphite SiC crucibles tuaj yeem siv rau kev tsim khoom semiconductor wafers thiab lwm yam khoom siv hluav taws xob.Graphite SiC Crucibles 'siab thermal conductivity thiab stability ua rau lawv zoo tagnrho rau siv nyob rau hauv high-temperature txheej txheem xws li tshuaj vapor deposition thiab siv lead ua loj hlob.

Kev tshawb fawb thiab kev loj hlob: Graphite SiC crucibles yog siv rau hauv cov ntaub ntawv tshawb fawb thiab kev loj hlob, qhov purity thiab stability yog qhov tseem ceeb.Lawv yog siv nyob rau hauv synthesis ntawm advanced cov ntaub ntawv xws li ceramics, composites, thiab alloys.

1. Cov ntaub ntawv zoo: Peb cov SiC Crucibles yog tsim los ntawm cov khoom siv raw khoom zoo.

2.High mechanical zog: Peb cov crucibles muaj lub zog txhua yam ntawm qhov kub thiab txias, ua kom muaj zog thiab ua haujlwm ntev.

3.Excellent thermal kev ua tau zoo: Peb cov SiC crucibles muab kev ua haujlwm zoo thermal, ua kom koj cov ntaub ntawv yaj sai thiab ua tau zoo.

4.Anti-corrosion zog: Peb SiC Crucibles muaj cov khoom tiv thaiv corrosion, txawm tias kub kub.

5.Electrical rwb thaiv tsev tsis kam: Peb cov crucibles muaj cov hluav taws xob rwb thaiv tsev zoo heev, tiv thaiv kev puas tsuaj hluav taws xob.

6.Professional technology txhawb: Peb muab kev tshaj lij thev naus laus zis los txhawb peb cov neeg siv khoom txaus siab rau lawv cov kev yuav khoom.

7.Customization muaj: Peb muab customization xaiv rau peb cov neeg muas zaub.

1. Cov khoom siv melted yog dab tsi?Puas yog txhuas, tooj liab, lossis lwm yam?

2. Lub peev xwm thauj khoom ib pob yog dab tsi?

3. Hom cua sov yog dab tsi?Puas yog hluav taws xob tsis kam, roj av, LPG, lossis roj?Kev muab cov ntaub ntawv no yuav pab peb muab cov lus qhia tseeb rau koj.

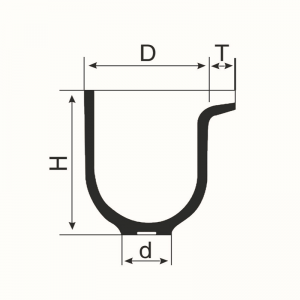

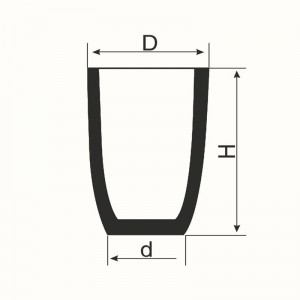

| Yam khoom | Sab nraud | Qhov siab | Sab hauv Dia | Hauv qab Dia |

| z803 ua | 620 | 800 | 536 ib | 355 |

| Z1800 | 780 ua | 900 | 680 | 440 |

| Z2300 | 880 ua | 1000 | 780 ua | 330 |

| z2700 ua | 880 ua | 1175 ib | 780 ua | 360 |

Q1.Koj puas muab cov qauv?

A1.Yog, cov qauv muaj.

Q2.MOQ yog dab tsi rau kev txiav txim mus sib hais?

A2.Tsis muaj MOQ.Nws nyob ntawm koj qhov kev xav tau.

Q3.Lub sijhawm khoom xa tuaj yog dab tsi?

A3.Cov khoom lag luam raug xa tawm hauv 7 hnub ua haujlwm, thaum cov khoom tsim khoom siv sijhawm 30 hnub.

Q4.Peb puas tuaj yeem tau txais kev txhawb nqa rau peb txoj haujlwm ua lag luam?

A4.Yog lawm, thov qhia rau peb ntawm koj qhov kev xav tau ntawm kev lag luam, thiab peb yuav muab cov lus qhia muaj txiaj ntsig thiab nrhiav kev daws teeb meem zoo tshaj plaws rau koj.

Tam sim no peb muaj cov neeg ua haujlwm tau zoo los daws cov lus nug los ntawm cov neeg siv khoom.Peb lub hom phiaj yog "100% cov neeg siv khoom txaus siab los ntawm peb cov khoom lag luam zoo, tus nqi nqe & peb cov neeg ua haujlwm pabcuam" thiab txaus siab rau qhov zoo heev ntawm cov neeg yuav khoom.Muaj ob peb lub Hoobkas, peb tuaj yeem muab ntau yam sib txawv ntawm Kub Muag Hoobkas 50g Hluav Taws Kub Ntsuas Smelting Kub Crucible, Peb tau saib xyuas ua ntej los teeb tsa lub koom haum ua lag luam me nrog koj mus ntev.Koj cov kev txheeb xyuas thiab cov lus qhia tau txais txiaj ntsig zoo heev.

Kub muag HoobkasTuam Tshoj Hluav Taws Kub Assay thiab Hluav Taws Xob Hluav Taws Xob, Peb cov khoom zoo yog ib qho ntawm cov kev txhawj xeeb loj thiab tau ua kom tau raws li tus neeg siv khoom tus qauv."Kev pabcuam cov neeg siv khoom thiab kev sib raug zoo" yog lwm qhov tseem ceeb uas peb nkag siab txog kev sib txuas lus zoo thiab kev sib raug zoo nrog peb cov neeg siv khoom yog lub zog tseem ceeb tshaj plaws los khiav nws ua lag luam mus ntev.