Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, eu tincidunt ante.

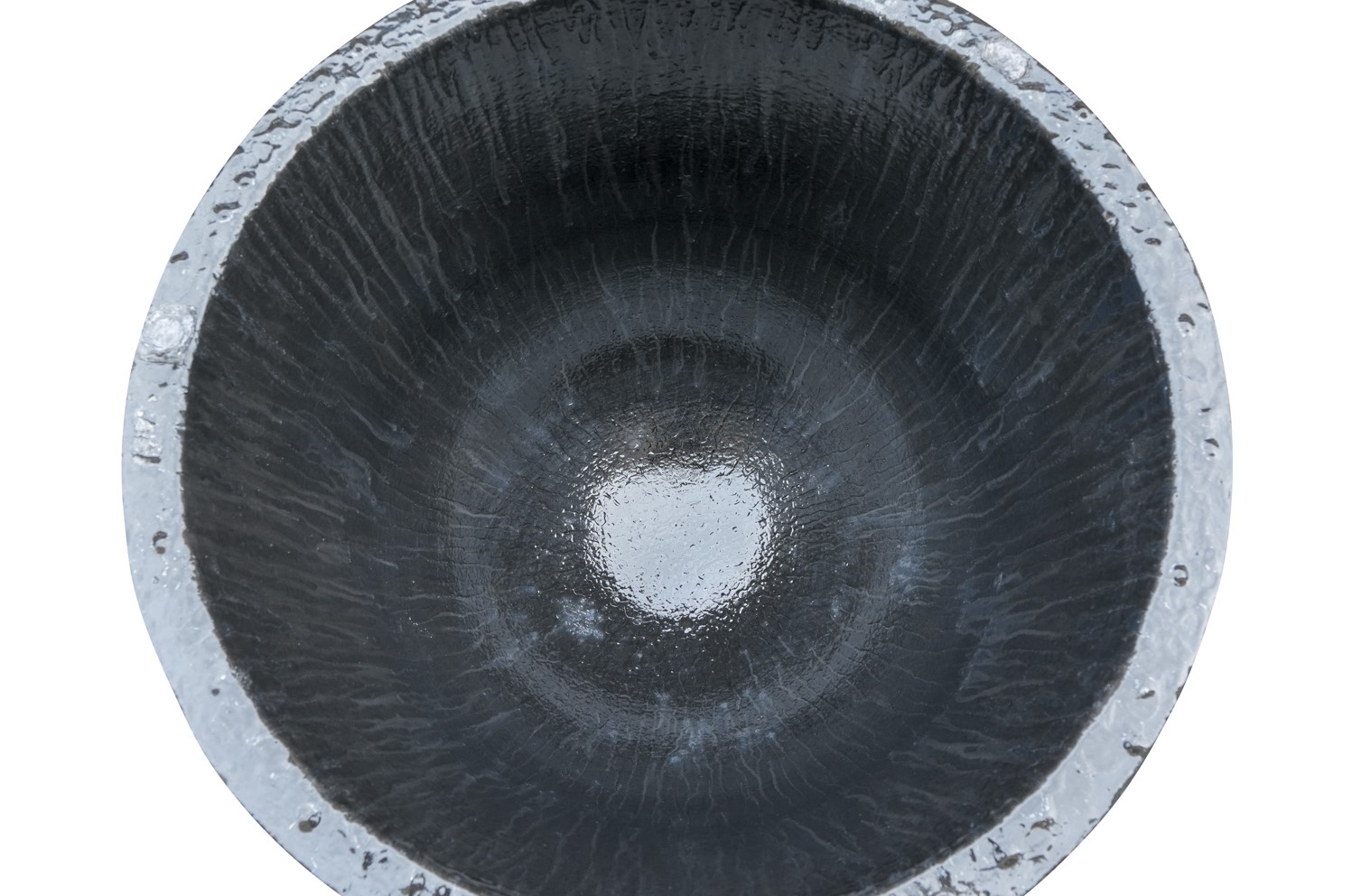

Graphite Crucibles Rau Melting Daim Ntawv BU

KHOOM NTA

Ceev ceev

Cov khoom siv thermal conductivity graphite txhim kho thermal efficiency los ntawm 30%, txo cov sij hawm melting.

Superior Thermal Shock Resistance

Resin-bonded technology withstands ceev cua sov thiab txias, tso cai rau them ncaj qha yam tsis muaj cracking.

Exceptional Durability

High mechanical zog tiv thaiv lub cev thiab tshuaj yaig rau lub neej ntev kev pab cuam.

TECHNICAL SPECIFICATIONS

| Graphite /% | 41.49 ib |

| SiC /% | 45.16 Nws |

| B/C /% | 4.85 ib |

| Al₂O₃ / % | 8.50 Nws |

| Qhov ceev / g·cm⁻³ | 2.20 |

| Pom tseeb porosity /% | 10.8 |

| Crushing zog / MPa (25 ℃) | 28.4 ib |

| Modulus ntawm rupture / MPa (25 ℃) | 9.5 ib |

| Hluav taws kub kub / ℃ | > 1680 |

| Thermal shock resistance / Sijhawm | 100 |

| No | Qauv | H | OD | BD |

| RA 100 | 100# | 380 | 330 | 205 |

| RA 200H400 | 180# | 400 | 400 | 230 |

| RA 200 | 200# | 450 | 410 | 230 |

| RA 300 | 300 # | 450 | 450 | 230 |

| RA 350 | 349# | 590 ua | 460 | 230 |

| RA 350H510 | 345 # | 510 | 460 | 230 |

| RA 400 | 400 # | 600 | 530 | 310 |

| RA 500 | 500 # | 660 | 530 | 310 |

| RA 600 | 501 # | 700 | 530 | 310 |

| RA 800 | 650 # | 800 | 570 ib | 330 |

| SIB 351 | 351# | 650 | 420 | 230 |

PROCESS PHEM

1. Precision Formulation

High-purity graphite + hwm silicon carbide + tus neeg sawv cev khi tus kheej.

.

2.Isostatic nias

Qhov ceev mus txog 2.2g / cm³ | Phab ntsa thickness kam rau ua ± 0.3m

.

3.High-kub Sintering

SiC particle recrystallization tsim 3D network qauv

.

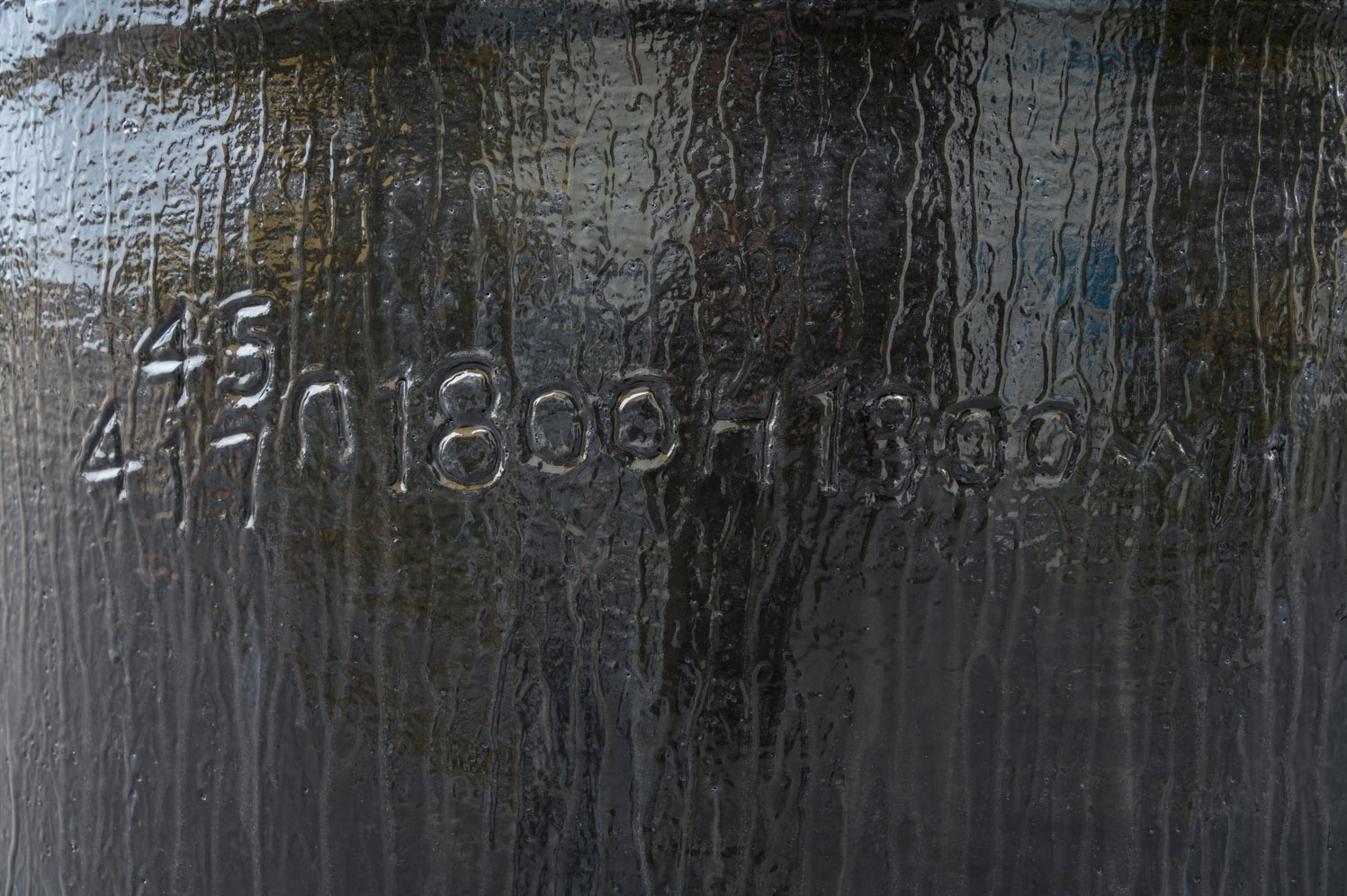

5.Kev soj ntsuam nruj nruj

Cim taug qab code rau tag nrho lifecycle traceability

.

4. Txhim kho qhov saum npoo

Anti-oxidation txheej → 3 × txhim kho corrosion kuj

.

6.Ntim Kev Nyab Xeeb

Shock-absorbent txheej + Moisture barrier + Reinforced casing

.

PRODUCT APPLICATION

Haum rau feem ntau cov hlau tsis-ferrous

Qhuav Aluminium

Melt tooj liab

Melt kub

Vim li cas thiaj xaiv peb

FAQS

Q1. Koj puas tuaj yeem ua raws li kev cai tshwj xeeb?

A: Yog, peb tuaj yeem hloov kho crucibles kom tau raws li koj cov ntaub ntawv tshwj xeeb lossis kos duab.

Q2. Koj txoj cai qauv yog dab tsi?

A: Peb tuaj yeem muab cov qauv ntawm tus nqi tshwj xeeb, tab sis cov neeg siv khoom yog lub luag haujlwm rau cov qauv thiab cov nqi xa khoom.

Q3. Koj puas kuaj tag nrho cov khoom ua ntej xa khoom?

A: Yog lawm, peb ua 100% kuaj ua ntej xa khoom kom paub meej cov khoom zoo.

Q4: Koj tsim thiab tswj kev lag luam mus ntev li cas?

A: Peb muab qhov tseem ceeb tshaj plaws thiab tus nqi sib tw kom ntseeg tau tias peb cov neeg siv khoom tau txais txiaj ntsig. Peb kuj saib xyuas txhua tus neeg siv khoom ua phooj ywg thiab ua lag luam nrog kev ncaj ncees thiab kev ncaj ncees, tsis hais lawv lub hauv paus chiv keeb. Kev sib txuas lus zoo, kev txhawb nqa tom qab muag, thiab cov lus tawm tswv yim ntawm cov neeg siv khoom kuj tseem ceeb rau kev tswj kom muaj kev sib raug zoo thiab kav ntev.

Q5: Yuav ua li cas tiv thaiv crucible cracking?

Tsis txhob them cov khoom txias rau hauv qhov kub kub (max ΔT <400 ° C).

Txias tus nqi tom qab melting <200 ° C / teev.

Siv cov ntsia hlau ntsia hlau ntsia hlau (tsis txhob cuam tshuam rau kev siv tshuab).

Q6: Yam tsawg kawg nkaus kom muaj nuj nqis (MOQ) yog dab tsi?

Qauv qauv: 1 pcs (cov qauv muaj).

Kev Cai Tsim: 10 daim (CAD kos duab xav tau).

Q7: Peb tuaj yeem lav qhov zoo li cas?

Peb lav qhov zoo los ntawm peb cov txheej txheem ntawm ib txwm tsim cov qauv ua ntej ua ntej ntau lawm thiab ua qhov kev tshuaj xyuas zaum kawg ua ntej xa khoom.

Q8: Koj lub peev xwm tsim khoom thiab lub sijhawm xa khoom yog dab tsi?

Peb lub peev xwm tsim khoom thiab lub sijhawm xa khoom nyob ntawm cov khoom tshwj xeeb thiab cov khoom xaj. Peb ua haujlwm ze nrog peb cov neeg siv khoom kom nkag siab txog lawv cov kev xav tau thiab muab lawv nrog kev kwv yees xa khoom raug.

Q9: Puas muaj qhov yuav tsum tau ua yam tsawg kawg nkaus uas kuv yuav tsum tau ua thaum xaj koj cov khoom?

Peb MOQ nyob ntawm cov khoom, thov hu rau peb kom paub ntxiv.

Case Study #1

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, eu tincidunt ante.

Case Study #2

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, eu tincidunt ante.

Cov ntawv pov thawj

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, eu tincidunt ante. Pellentesque aliquet feugiat tellus, thiab feugiat tortor porttitor vel. Nullam id scelerisque magna. Curabitur placerat sodales placerat. Nunc dignissim ac velit vel lobortis.

- Jane Doe

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, eu tincidunt ante. Pellentesque aliquet feugiat tellus, thiab feugiat tortor porttitor vel. Nullam id scelerisque magna. Curabitur placerat sodales placerat. Nunc dignissim ac velit vel lobortis. Nam luctus mauris elit, sed suscipit nunc ullamcorper ut.

- John Doe