Graphite Crucible Nrog Spout rau Melting Kub thiab Nyiaj

KHOOM NTA

Superior Thermal conductivity

Qhov sib xyaw tshwj xeeb ntawm silicon carbide thiab graphite ua kom muaj cua sov sai thiab zoo ib yam, txo qis rau lub sijhawm melting.

Kub kub Resistance

Qhov sib xyaw tshwj xeeb ntawm silicon carbide thiab graphite ua kom muaj cua sov sai thiab zoo ib yam, txo qis rau lub sijhawm melting.

Corrosion Resistance

Qhov sib xyaw tshwj xeeb ntawm silicon carbide thiab graphite ua kom muaj cua sov sai thiab zoo ib yam, txo qis rau lub sijhawm melting.

TECHNICAL SPECIFICATIONS

Kev xaiv khoom siv:

Graphite Crucible nrog Spout yog tsim los ntawm silicon carbide graphite, sib txuas cov thermal conductivity ntawm graphite nrog lub zog ntawm silicon carbide. Qhov kev xaiv cov khoom no ua kom muaj kev tiv thaiv oxidation siab, ruaj khov ntawm qhov kub thiab txias, thiab txhim kho hlau purity los ntawm kev txo cov impurities thaum lub sij hawm melting txheej txheem.

| Graphite /% | 41.49 ib |

| SiC /% | 45.16 Nws |

| B/C /% | 4.85 ib |

| Al₂O₃ / % | 8.50 Nws |

| Qhov ceev / g·cm⁻³ | 2.20 |

| Pom tseeb porosity /% | 10.8 ib |

| Crushing zog / MPa (25 ℃) | 28.4 ib |

| Modulus ntawm rupture / MPa (25 ℃) | 9.5 ib |

| Hluav taws kub kub / ℃ | > 1680 |

| Thermal shock resistance / Sijhawm | 100 |

| Tsis muaj. | H (mm) | D (mm) | d (mm) | L (mm) |

|---|---|---|---|---|

| TIAB SA 173 G | 490 ib | 325 | 240 | 95 |

| TP 400 G | 615 | 360 | 260 | 130 |

| TIAB SA 400 | 665 ib | 360 | 260 | 130 |

| TIAB SA 843 | 675 ib | 420 | 255 | 155 |

| TIAB SA 982 | 800 | 435 ib | 295 | 135 |

| TIAB SA 89 | 740 ib | 545 ib | 325 | 135 |

| TP 12 | 940 ua | 440 | 295 | 150 |

| TP 16 | 970 ua | 540 | 360 | 160 |

PROCESS PHEM

1. Precision Formulation

High-purity graphite + hwm silicon carbide + tus neeg sawv cev khi tus kheej.

.

2.Isostatic nias

Qhov ceev mus txog 2.2g / cm³ | Phab ntsa thickness kam rau ua ± 0.3m

.

3.High-kub Sintering

SiC particle recrystallization tsim 3D network qauv

.

4. Txhim kho qhov saum npoo

Anti-oxidation txheej → 3 × txhim kho corrosion kuj

.

5.Kev soj ntsuam nruj nruj

Cim taug qab code rau tag nrho lifecycle traceability

.

6.Ntim Kev Nyab Xeeb

Shock-absorbent txheej + Moisture barrier + Reinforced casing

.

PRODUCT APPLICATION

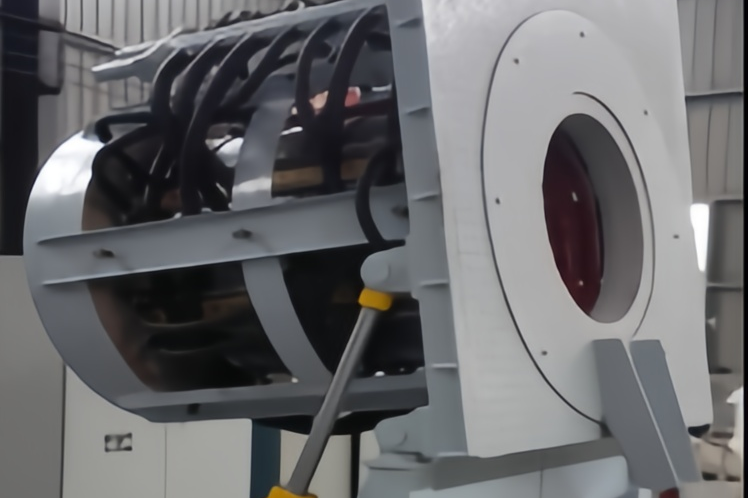

Gas Melting Rauv

Induction Melting Rauv

Resistance Melting Rauv

Vim li cas thiaj xaiv peb

FAQS

Q1: Dab tsi yog qhov zoo ntawm silicon carbide graphite crucibles piv rau cov tsoos graphite crucibles?

✅Kev kub siab dua: tuaj yeem tiv taus 1800 ° C mus sij hawm ntev thiab 2200 ° C luv luv (vs. ≤1600 ° C rau graphite).

✅Ntev Lifespan: 5x zoo dua thermal shock resistance, 3-5x ntev kev pab cuam lub neej.

✅Zero Contamination: Tsis muaj cov pa roj carbon nkag, ua kom cov hlau purity molten.

Q2: Cov hlau twg tuaj yeem yaj hauv cov crucibles?

▸Hom Hlau: Aluminium, tooj liab, zinc, kub, nyiaj, thiab lwm yam.

▸Reactive hlau: Lithium, sodium, calcium (yuav tsum tau Si₃N₄ txheej).

▸Refractory hlau: Tungsten, molybdenum, titanium (yuav tsum tau lub tshuab nqus tsev / inert gas).

Q3: Puas yog crucibles tshiab yuav tsum tau kho ua ntej siv?

Yuav Tsum Ci: Maj mam kub rau 300 ° C → tuav rau 2 teev (tshem tawm cov dej seem seem).

Thawj Melt Pom Zoo: Qhuav ib pawg ntawm cov khoom seem ua ntej (ua ib txheej tiv thaiv).

Q4: Yuav ua li cas tiv thaiv crucible cracking?

Tsis txhob them cov khoom txias rau hauv qhov kub kub (max ΔT <400 ° C).

Txias tus nqi tom qab melting <200 ° C / teev.

Siv cov ntsia hlau ntsia hlau ntsia hlau (tsis txhob cuam tshuam rau kev siv tshuab).

Q5: Yuav ua li cas tiv thaiv crucible cracking?

Tsis txhob them cov khoom txias rau hauv qhov kub kub (max ΔT <400 ° C).

Txias tus nqi tom qab melting <200 ° C / teev.

Siv cov ntsia hlau ntsia hlau ntsia hlau (tsis txhob cuam tshuam rau kev siv tshuab).

Q6: Yam tsawg kawg nkaus kom muaj nuj nqis (MOQ) yog dab tsi?

Qauv qauv: 1 pcs (cov qauv muaj).

Kev Cai Tsim: 10 daim (CAD kos duab xav tau).

Q7: Lub sijhawm ua haujlwm yog dab tsi?

⏳Cov khoom hauv Tshuag: Nkoj hauv 48 teev.

⏳Custom Orders: 15-25hnubrau ntau lawm thiab 20 hnub rau pwm.

Q8: Yuav ua li cas txiav txim siab yog tias lub crucible tau ua tsis tiav?

Kev tawg> 5mm ntawm phab ntsa sab hauv.

Hlau nkag qhov tob> 2mm.

Deformation> 3% ( ntsuas sab nraud hloov pauv).

Q9: Koj puas muab cov txheej txheem melting?

Cov cua kub nkhaus rau cov hlau sib txawv.

Inert gas flow rate tshuab xam zauv.

Slag tshem tawm video tutorials.