Lorem ipsum dolor sit amet consectetur adipiscing elit.

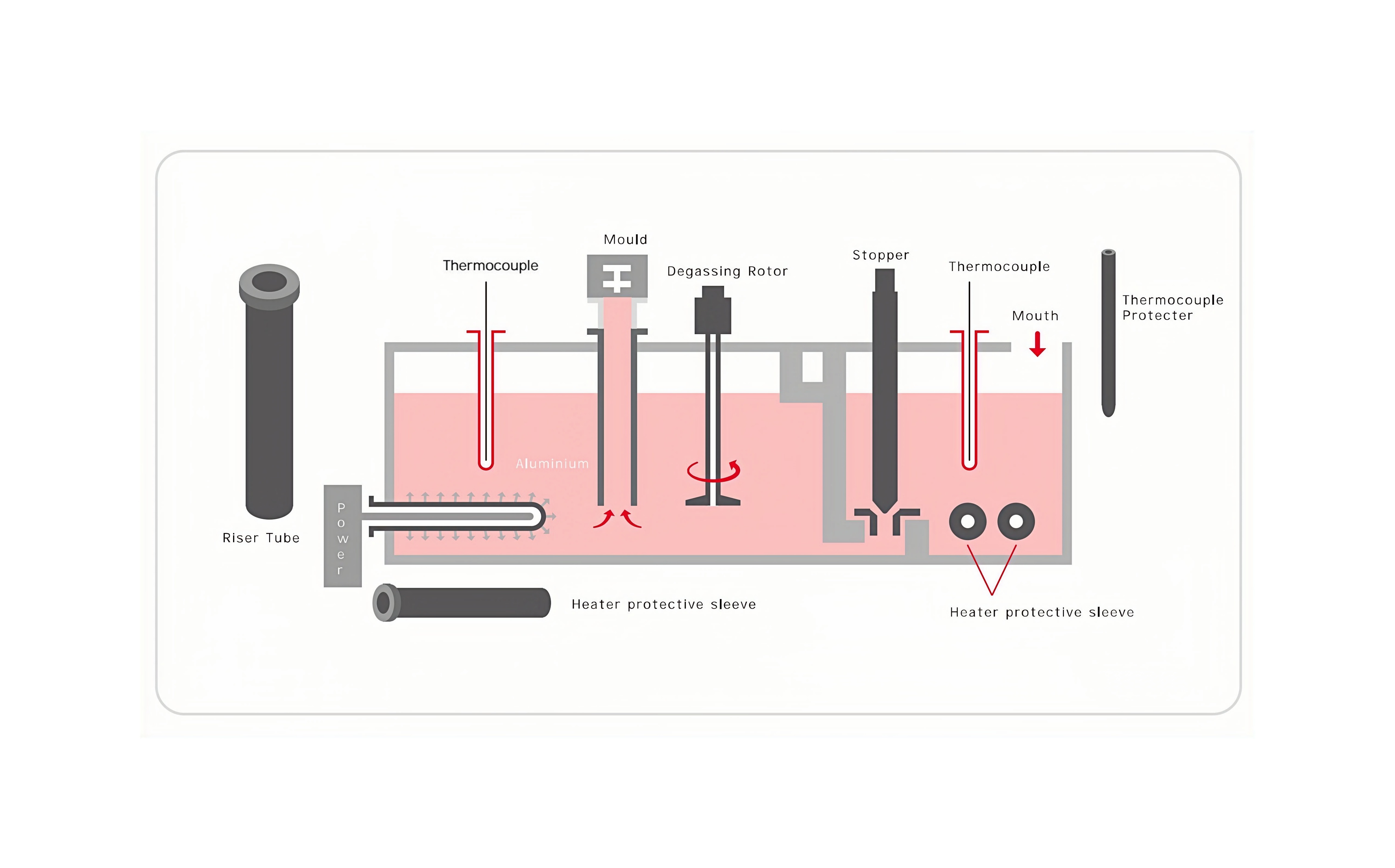

Silicon Nitride Degassing Rotor hauv Degassing Tshuab rau Aluminium Foundry

Cov khoom siv muaj zog heev

High Wear Resistance

Siab Corrosion Resistance

Cov yam ntxwv tseem ceeb

Lub silicon nitride degassing rotor, nrog silicon nitride raws li nws cov khoom tseem ceeb, integrates ultra-siab-ceev tsim thiab meej structural tswj, ua tau zoo breakthroughs nyob rau hauv lub degassing txheej txheem ntawm txhuas ua. Nws cov yam ntxwv tseem ceeb yog raws li nram no:

I. Cov Khoom Siv Zoo: Kev Tiv Thaiv Kub, hnav tsis kam, thiab tsis muaj paug

- Inherent Superiority Over Graphite: Lub rotor thiab impeller yog ua los ntawm silicon nitride. Nws cov kev ua tiav thiab lub zog nyob deb dhau ntawm cov graphite, txhawb kev sib hloov ntawm ultra-siab ceev (txog 8,000 rpm) thiab txuas ntxiv lub neej kev pab cuam.

- High - Temperature Oxidation Resistance: Yuav luag tsis muaj oxidation nyob rau hauv qhov kub thiab txias ib puag ncig, kom tsis txhob muaj teeb meem ntawm "paj paug molten aluminium" thiab xyuas kom meej cov khoom purity.

- Chemical Inertness: Nws tsis hnov mob nrog molten aluminium, ruaj khov kho cov nyhuv degassing zoo rau lub sijhawm ntev. Tsis tas yuav txhawj xeeb txog cov khoom degradation cuam tshuam rau kev ua haujlwm.

II. Tus qauv Precision: ruaj khov siab - Kev khiav hauj lwm ceev, tiaj tus Molten nto

- Ultra - High Concentricity: Lub concentricity ntawm lub rotor yog nruj me ntsis tswj nyob rau hauv 0.2 hli (qhov twg 1 "silk" = 0.01 hli). Thaum lub sij hawm kev sib hloov ceev ceev, qhov kev vibration yog me me, tshem tawm cov kua dej hloov pauv los ntawm eccentricity.

- Precision Connection System: Lub rotor lub taub hau thiab cov ncej txuas yog ua los ntawm cov hlau tsis muaj steel, nrog rau kev ua tiav tiav mus txog qib 0.01 - hli. Ua ke nrog high-precision sib dhos, "concentric high-speed tsav" ua tiav, txo qhov kev hloov pauv ntawm cov molten aluminium nto thiab ua kom ruaj khov ntau lawm.

III. Kev Txhim Kho Kev Ua Haujlwm: Ua tau zoo, kev cia siab, thiab txo tus nqi

- High Density + High Strength: Ob lub zog no ua kom muaj kev ntseeg tau ntawm cov qauv thiab tsis muaj kev pheej hmoo deformation thaum lub sijhawm ua haujlwm ultra-high-speed, ua rau nws hloov tau rau kev ua haujlwm hnyav.

- Distinct Comparative Advantages: Muab piv nrog graphite rotors, nws yuav siv sij hawm ib qho kev coj ua nyob rau hauv kev pab cuam lub neej, muaj kuab paug tsis kam, thiab siab ceev adaptability. Nws txo qhov zaus ntawm kev kaw haujlwm thiab tsis ncaj qha txhim kho kev tsim khoom.

Technical Specifications

| Nta | Cov txiaj ntsig |

|---|---|

| Khoom siv | High-density graphite |

| Ua haujlwm kub siab tshaj plaws | Txog li 1600 ° C |

| Corrosion Resistance | Zoo heev, tswj kev ncaj ncees ntawm molten aluminium |

| Kev Pabcuam Lub Neej | Ntev ntev, haum rau kev rov siv dua |

| Gas Dispersion Efficiency | Maximized, ua kom cov txheej txheem purification zoo ib yam |

Yuav Ua Li Cas Xaiv Lub Degassing Impeller?

Hom F Rotor Φ250 × 33

Vim qhov tsim tshwj xeeb ntawm nws cov impeller grooves thiab cov hniav sab nrauv, Hom F tsim cov npuas me me. Nws qhov loj impeller loj tuaj yeem txhim kho kev tawg ntawm cov txhuas txhuas, thaum lub impeller thinner minimizes deg fluctuations ntawm yaj.

Daim ntawv thov: Haum rau loj tiaj tiaj ingot thiab round bar melting kab (ob chav - rotor los yog triple - rotor degassing systems).

Hom B Rotor Φ200 × 30

Lub impeller qauv ntawm hom B tsim kom muaj siab txaus los tsim cov npuas me me thaum txo cov thermal shock.

Daim ntawv thov: Haum rau kev nruam casting thiab dov melting kab (ib zaug - rotor degassing systems).

Hom D Rotor Φ200 × 60

Hom D nta ob txheej khob cij - zoo li lub log tsim, ua kom muaj kev ntxhov siab zoo thiab nthuav tawm ntawm npuas.

Daim ntawv thov: Haum rau high-flow melting kab (ob chav - rotor degassing khoom).

Hom A

Hom C

Silicon Nitride Ceramic Cov Khoom Pom Zoo Zoo

Lub neej ua haujlwm ntev thiab cov nqi kho mob tsawg

Vim muaj qhov kub thiab txias zog, muaj zog thermal shock resistance, thiab zoo corrosion kuj ntawm silicon nitride ceramics, lawv cov kev pab cuam lub neej feem ntau ncav cuag ntau tshaj ib xyoos, yog li txo cov nqi hloov thiab tu.

Tsis muaj kuab paug rau molten aluminium

Silicon nitride muaj qhov ntub dej tsawg rau cov hlau molten thiab tsis tshua muaj tshwm sim nrog molten aluminium. Yog li ntawd, nws yuav tsis ua rau muaj kuab paug thib ob rau molten aluminium, uas yog kev pab zoo rau stabilizing qhov zoo ntawm cov khoom cam khwb cia.

Yooj yim installation thiab txij nkawm

Silicon nitride ceramics tuaj yeem tuav lub zog flexural ntau dua 500MPa thiab zoo thermal shock tsis kam qis dua 800 ℃. Yog li, phab ntsa thickness ntawm cov khoom tuaj yeem ua thinner. Tsis tas li ntawd, vim nws tsis tshua muaj dej tsis zoo rau cov hlau molten, tsis tas yuav tsum tau siv cov txheej txheem saum npoo, uas tseem ua rau kev txhim kho thiab kho cov cuab yeej yooj yim dua.

Cov lus sib piv ntawm tus nqi-kev ua tau zoo ntawm cov khoom siv immersion hauv kev lag luam aluminium

| Qeb | Index | Silicon Nitride | Cast Iron | Graphite | Cov tshuaj tiv thaiv-Sintered SiC | Carbon-Nitrogen Bonded | Aluminium Titanate |

|---|---|---|---|---|---|---|---|

| Cua sov tiv thaiv Tube | Lub neej Ratio | > 10 | — | — | 3–4 | 1 | — |

| Tus nqi sib piv | > 10 | — | — | 3 | 1 | — | |

| Nqi-Kev Ua Haujlwm | Siab | — | — | Nruab nrab | Tsawg | — | |

| Lifting Tube | Lub neej Ratio | > 10 | 1 | — | — | 2 | 4 |

| Tus nqi sib piv | 10–12 | 1 | — | — | 2 | 4–6 | |

| Nqi-Kev Ua Haujlwm | Siab | Tsawg | — | — | Nruab nrab | Nruab nrab | |

| Degassing Rotor | Lub neej Ratio | > 10 | — | 1 | — | — | — |

| Tus nqi sib piv | 10–12 | — | 1 | — | — | — | |

| Nqi-Kev Ua Haujlwm | Siab | — | Nruab nrab | — | — | — | |

| Sealing Tube | Lub neej Ratio | > 10 | 1 | — | — | — | 4–5 |

| Tus nqi sib piv | > 10 | 1 | — | — | — | 6–7 | |

| Nqi-Kev Ua Haujlwm | Siab | Tsawg | — | — | — | Nruab nrab | |

| Thermocouple Protection Tube | Lub neej Ratio | > 12 | — | — | 2–4 | 1 | — |

| Tus nqi sib piv | 7–9 | — | — | 3 | 1 | — | |

| Nqi-Kev Ua Haujlwm | Siab | — | — | Nruab nrab | Tsawg | — |

Cov Neeg Siv Khoom

Factory Certifications

Kev ntseeg siab los ntawm Cov Thawj Coj Hauv Ntiaj Teb - Siv hauv 20+ lub teb chaws