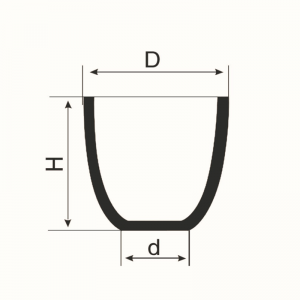

Crucible rau Foundry rau Melting Metals

Ntsiab nta

Peb Crucibles rau Foundryexcel nyob rau hauv huab ib puag ncig, withstanding kub mus txog1600 ° C. Cov khoom siv silicon carbide ua kom zoo thermal poob siab tsis kam, txhais tau tias lawv tuaj yeem tswj qhov kub hloov pauv sai yam tsis muaj qhov tawg. Ntxiv rau, cov khoom tsis muaj zog txo qis kev sib kis - zoo tagnrho rau cov hlau purity siab.

Cov txiaj ntsig dhau ntawm cov neeg sib tw

- Durability:Tsim los rau lub neej ntev, peb cov crucibles muab kev txuag nyiaj ntau dhau sijhawm.

- Advanced Technology:Siv high-pressure molding rau uniform ntom thiab lub zog.

- Nqi-zoo:Nrog lub neej ntev ntawm ob peb xyoos, lawv txo cov nqi ua haujlwm tag nrho.

Daim ntawv thov

Cov crucibles no yog qhov tseem ceeb rau cov chaw tsim khoom ua haujlwm nrog cov hlau tsis muaj hlau xws li txhuas, tooj liab, thiab tooj dag, ua rau lawv muaj ntau yam rau ntau yam kev siv, los ntawm metallurgy mus rau iav ntau lawm.

Technical Specifications

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

FAQs

Hom hlau twg kuv tuaj yeem yaj nrog cov crucibles no?

Peb cov crucibles zoo tagnrho rau txhuas, tooj liab, tooj dag, thiab lwm yam.

Dab tsi yog qhov kub siab tshaj plaws cov crucibles tuaj yeem tiv taus?

Lawv tuaj yeem tswj qhov kub txog li 1600 ° C, ua rau lawv haum rau cov txheej txheem melting hnyav.

Koj puas muab customization?

Yog lawm, peb muab kev pabcuam OEM raws li koj qhov tshwj xeeb.

Lub tuam txhab zoo

Peb leverage xyoo ntawm kev txawj ntse hauv kev lag luam casting. Peb txoj kev cog lus rau kev ua tau zoo, ua ke nrog cov kev daws teeb meem tshiab thiab kev txhawb nqa rau cov neeg siv khoom, ua kom koj tau txais cov khoom zoo tshaj plaws rau koj cov kev xav tau. Xaiv pebCrucibles rau Foundrythiab hloov koj cov kev paub casting hlau!